What is Total Productive Maintenance(TPM)?

It's by far probably the most tough part to implement. As soon as a high diploma of solidity generates with the 5S, a corporation can start implementing the entire Productive Maintenance principles in earnest. So, The eight pillars of TPM are normally targeted at proactive and preventative strategies for enhancing gear reliability. Fix Bottlenecks: Determine and tackle slowdowns in your process. Steadiness Work: Ensure that work is evenly distributed. Simplify Duties: Streamline your processes for better workflow. Pull techniques respond to buyer demand. It helps scale back stock and meet needs quicker. Kanban boards are a useful gizmo for managing this. Demand-Based mostly Manufacturing: Produce gadgets as customers need them. Lower Stock: Keep solely necessary stock ranges. Kanban Boards: Use visual instruments to manage workflow and inventory. Seeing your processes makes them easier to know.

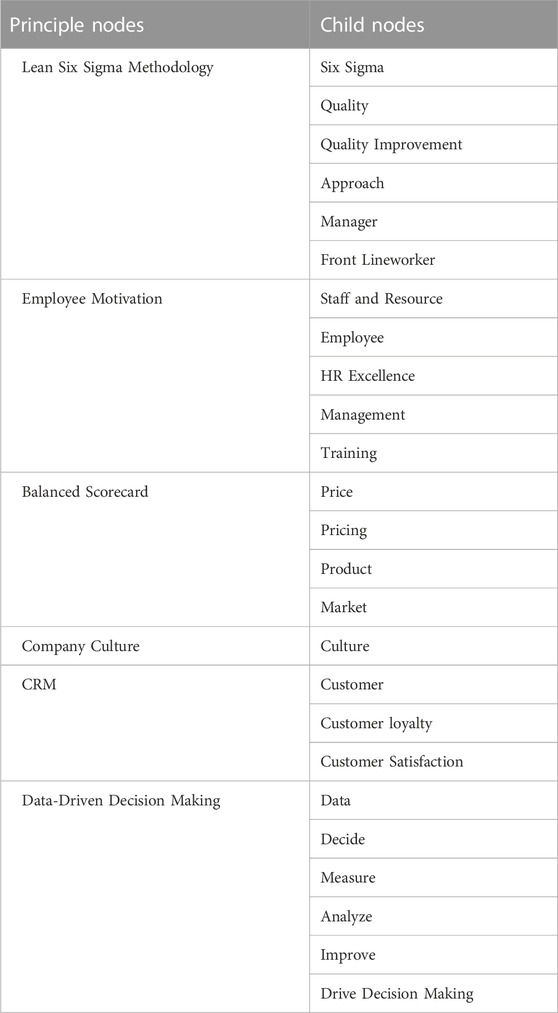

A stitch in time saves 9. Unscheduled downtime is the enemy of productiveness and goes hand-in-hand with larger costs. Tools like CMMS software program and EAM methods keep your belongings working effectively and reduce machine failures. When push comes to shove, it’s all concerning the completed product. High quality control administration ensures you produce items in line with set parameters and specs. Compliance checks and enterprise quality management software program present a serving to hand. All the world’s equipment, software and planning won’t increase productivity without individuals administration. Finding the right group members, providing coaching and improvement, sustaining security and bettering effectively-being are key to optimizing productiveness. Worker engagement and HRIS management software program manage insurance policies and keep employees motivated. Manufacturing excellence doesn’t occur in a single day. A strategy geared to continuous enchancment is a product of a quality manufacturing operations course of or loads of trial and error. Minimized delays, breakdowns and manufacturing stops - Clean, well-lubricated gear is much less probably to interrupt down unexpectedly. Secondly, making basic maintenance duties and inspections the duty of your entire facility relatively than just the maintenance team will increase the probability that defects can be detected upfront. Decrease upkeep costs - In the long run, lowering unplanned downtime with TPM can save organizations a whole lot of hundreds of dollars each year. Better worker retention and engagement - A clear, hazard-free workspace where technicians have access to instruments which might be in good working condition is vital to recruitment and retention in manufacturing plants. There are eight pillars of TPM practices that organizations should put in place each day as they attempt for complete perfection.

Minimizes manufacturing prices: Since TPM improves total gear effectiveness (OEE), you may higher management tools stoppage time and unplanned repairs. This decline in maintenance prices leads to larger profits. Boosts worker satisfaction: TPM ensures equipment longevity and improves employee happiness with cross-departmental information sharing and equipment possession. Minimizes defects: A consistent best production engineering services in Gujarat line improves product quality and pace of delivery. If that has piqued your curiosity, let's see learn how to calculate complete productive maintenance and implement it at your facility. Dianne Feinstein (D-CA) and Susan Collins (R-ME), would give the FDA extra oversight over the trade normally. So what’s the answer? How can cosmetics companies mired in previous processes, limited technologies and sluggish-transferring product journeys possibly hope to speed up time to market while also remaining compliant with ever changing regulations?